OSHA Safety Compliance Recordkeeping: What You Need To Know

Maintaining OSHA safety compliance and keeping up with the latest rules can be a challenge. First of all, companies that are not considered “compliant” if their logs are not completed or the summary is not posted. The second thing to note is that there are differences in what you’re required to report to OSHA, and what you’re required to record.

What Do We Need To Record For OSHA Safety Compliance?

- Fatalities – Any work-related fatality requires both reporting and recording.

- Employee Loses Consciousness – If an employee loses consciousness on the job; it’s a recordable incident.

- Lost Time Injury – If an employee suffers a work-related injury or illness that causes lost work time, job transfer, or restriction, that injury must be recorded, along with the number of days away from work or on restricted duty. The day of the injury is not counted, but all subsequent days, including weekends and holidays, up to 180 days, must be counted and recorded.

- Occupational Hearing Loss – There are very specific criteria for determining whether or not you must record an employee’s work-related hearing loss. OSHA publishes a decision tree for determining whether or not you need to record a specific incident.

- Needle Sticks And Sharps Injuries – All injuries caused by work-related use of needles and sharps are recordable.

- Transmission Of Tuberculosis – Any case of tuberculosis transmission through job-related activities must be recorded.

- Any Injury Requiring Care Beyond First Aid – Any time an employee is injured and he or she requires medical treatment, as opposed to first aid, that’s a recordable “Other” incident.

What’s The Difference Between Medical And First Aid Treatment?

OSHA has very specific guidelines for determining whether treatment for a work-related injury is medical or first aid. It’s critical that you understand that these specific definitions exist, and use them in your decision to record, rather than relying on your own opinion of the level of treatment. OSHA fines were significantly increased in January 2016, and making mistakes in your recordkeeping could prove very costly. Here are some guidelines covering common work-related illness and injury situations.

OSHA-Defined First Aid

- OTC Medicine used at non-prescription dosage.

- Tetanus Immunization following a work-related injury like a puncture wound.

- Wound Cleaning And Debridement – For any area other than the eye, cleaning or flushing of a wound, or removing debris using simple means like tweezers or cotton swabs are considered first aid.

- Wound Covering – Covering wounds with bandages, gauze pads, butterfly bandages or Steri-Strips™ is defined as first aid treatment.

- Hot Or Cold Therapy – Treating an injury with heating pads, ice packs, or chemical packs to provide hot or cold relief falls under first aid treatment.

- Temporary Immobilization For Transport – Use of a splint, sling, c-collar, or backboard to transport an accident victim safely to help is defined as first aid.

- Non-Rigid Support – Elastic bandages, sports tape, non-rigid back belts and wraps are considered first aid.

- Fluid Pressure Relief – Lancing and draining a blister, or drilling a fingernail or toenail to relieve fluid pressure is first aid.

- Eye Treatment And Protection –Removing debris with a cotton swab, flushing an eye injury or administering an eye patch to protect an injured or irritated eye is defined as first aid.

- Massaging – Massage is considered first aid, when it is not part of physical therapy or chiropractic treatment.

OSHA-Defined Medical Treatment

- OTC Medicine — Over-the-counter medicine administered at prescription strength is no longer considered first aid, but is medical treatment.

- Immunizations – Immunizations, other than tetanus, such as hepatitis B or rabies, are defined as medical treatment.

- Wound Closure – If closure methods like sutures or staples are used to close a wound, it’s a medical treatment, rather than first aid.

- Rigid Immobilizers – Except for temporary immobilizing for safe transport, explained above, any use of a device that uses rigid stays to immobilize an injured body part is considered medical treatment.

- Eye Treatment – Any treatment to the eye beyond flushing, swabbing as described above, or covering with a patch is defined as medical.

Pulling It All Together

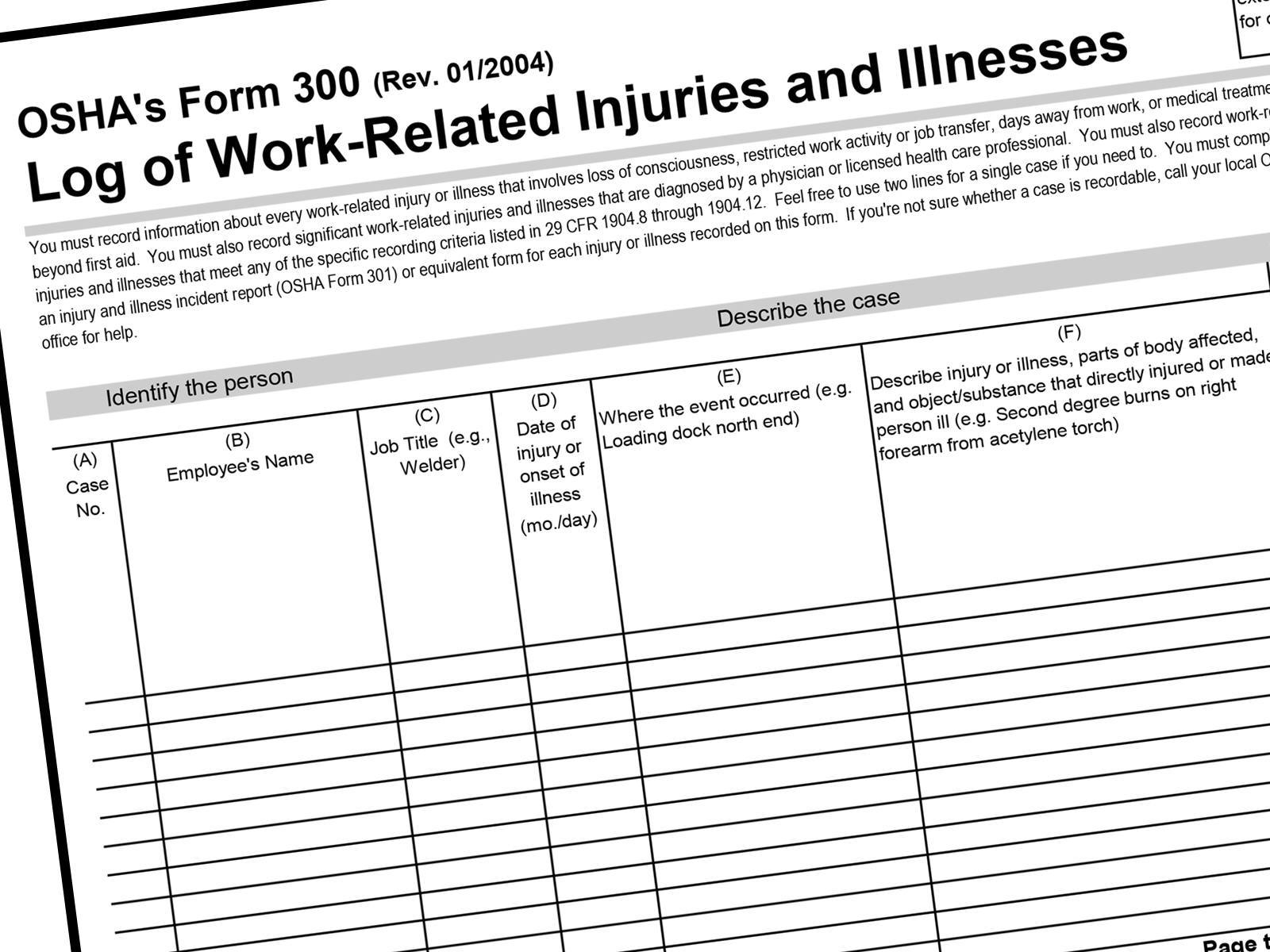

There are three basic parts of your OSHA safety compliance recordkeeping: An OSHA 300 log; OSHA 301 Injuries and Illnesses Incident Report forms, which are filed for every recordable incident; and the OSHA 300A annual report and 300A summary, which has to be filed by February 1 for the previous year, and must remain posted until April 30 of the year in which it’s posted. You can download printable or fillable form versions online. Your company needs to maintain complete records for the past five years, in addition to the current year’s form 300 and any 301 forms, in order to remain in compliance.

It’s critical for your company that all of your managers and supervisory staff members are trained on your OSHA safety compliance program, and they know what to do when an employee becomes ill or injured. It’s also important to refresh that training periodically, not only to ensure that your team remembers what to do, but also to update them on any policy changes and new guidelines.

Plan, Prepare, And Prosper

Managing your company’s OSHA safety compliance program can be time-consuming and headache inducing. Not only do you need to have a plan that covers all aspects of compliance you are liable for, and train your supervisory staff on that plan, but you also need to review that plan annually. An annual review should indicate any updates needed to comply with new rules and guideline, and it should also evaluate the previous year’s records for shortcomings in the system. Is there a pattern in safety issues or in recording or reporting? Those need to be addressed, and solutions should be included in the current year’s training program.

OSHA safety compliance consultants, like the experts at Optimum Safety Management, can help simplify the entire process for you, while keeping your people safer and protecting your business from unnecessary expenses in the form of fines and increased Workers’ Compensation premiums. Whether your company needs to design a health and safety program from the ground up, or you just need to evaluate and update your current program, you’ll benefit at every stage from working with a consultant whose entire job revolves around staying current on OSHA regulations.