We all know injuries can be expensive, but how many people know exactly how much an injury costs? Finding the real cost of a workplace injury not only shows the financial implications but forces us to think about the auxiliary effects of an incident. When a worker gets injured, what are the effects on production, quality, morale and ultimately, the bottom line?

Whatever the type of injury, there are costs associated you may not be aware of.

Types of Costs Associated with Workplace Injuries

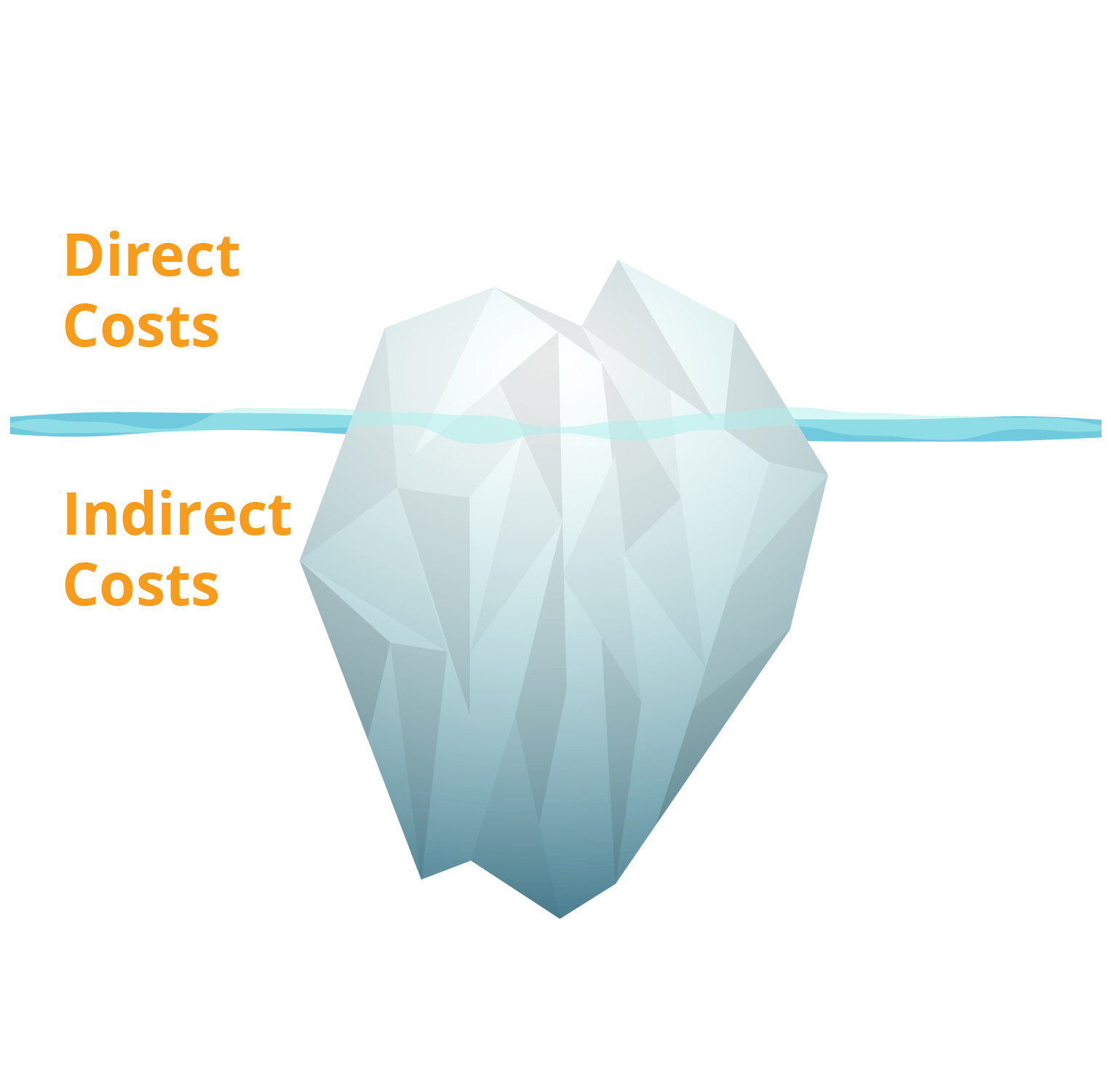

In any injury, there are two types of costs: direct costs and indirect costs. Let’s start by examining each type.

Direct Costs

The direct costs are what most people are familiar with. Typically, the direct cost is the worker’s compensation claim managed through the company’s insurance agency. While the cost can range significantly depending on the organization’s Experience Modification Rate, the average cost of a workplace injury claim is $40,000 based on the National Council on Compensation Insurance’s Workers Compensation Statistical Plan database.

Direct Cost = $40,000

Indirect Costs

Indirect costs are much less familiar but are certainly just as important as direct costs (if not more so). To give a simple visual reference, think of injury costs as an iceberg. The direct costs are what we can see and the indirect costs are the much larger, much deeper parts we cannot see without careful inspection.

Below are examples of indirect costs associated with an injury. While this list covers many areas, it is not by any means an exhaustive list. Each company will have additional factors depending on the type of operation.

Quick Tip: To get an idea of the costs associated with an injury in your operation, draw a simple storyboard of what happens when an injury occurs. If you operate a manufacturing facility, draw each action that occurs when a worker on the production line incurs a laceration. Does the production line shut down? How many employees stop other work to help? Is the affected person taken to the hospital?

Outlining each of these steps will help to highlight all the additional resources involved in caring for an injury. Having trouble getting started? Call our SafetyHelpline™ at (888-707-2338) and we’ll help to get ideas flowing.

Examples of Indirect Costs

- Wages during work stoppage after injury: time to assess worker condition and condition of equipment, co-workers who stop to help, internal first responders, time spent seeking medical treatment

- OSHA fines and enforcement actions: expense of fines and penalties, hiring an attorney to help challenge or abate citations, administrative time, consultant’s fees

- Recovery of lost production: overtime pay, hiring/training temp workers, reduced quality and productivity, accommodating injured workers’ physical limitations

- Additional human resources: legal counsel, 3rd party consultants, medical advisor)

- Administrative time spent by staff: HR, safety personnel, and supervisors to complete documentation, coordinate return to work and investigation reporting

- Increase in workers compensation coverage: higher premiums

These costs are expansive and can be difficult to measure. Thankfully for us, many researchers have observed this issue and identified methods for evaluating the indirect costs. One study conducted by researchers from the Liberty Mutual Research Institute for Safety, Harvard University and University of Wisconsin-Oshkosh found that for every dollar spent on direct costs, about $2.12 would be spent on indirect costs. (This study also found that, on average, every dollar spent on improving workplace safety returned $4.41. Now that’s an ROI we can get behind.)

Another study focused on the construction industry found the ratio between indirect and directs to be 4:1 and in some cases as high as 17:1. Certainly these ratios vary depending on the scope and magnitude of the incident, but in any case, the indirect costs far outweigh the direct costs.

To be conservative (and for simple math), we’ll assume an average ratio of 2:1 for indirect to direct costs.

Indirect Cost = Direct Cost x 2

Indirect Cost = $80,000 = $40,000 x 2

The Total Cost of an Injury

Using the numbers from direct and indirect costs, we can find the real cost of a workplace injury.

Total Cost = Direct Cost + Indirect Cost

Total Cost = $120,000 = $40,000 + $80,000

So What’s the Bottom Line?

On average, employers will spend $120,000 on each workplace injury. For companies operating at a 10% profit margin, you’ll need an additional $1.2 million in sales to pay for the injury.

Looking at an injury from a holistic perspective, we can see it not only affects the individual who got injured, but the entire company. An injury hurts production, lowers morale, requires excess administrative effort and ultimately removes money from the bottom line.

Here are the real questions:

- How much are injuries costing your company every year and what are you going to do about it?

- Now that you have this information, what will you do with it?

To speak with a member of Optimum’s team, don’t hesitate to call the SafetyHelpline™. We’re here to help you on the journey to zero workplace injuries.

888-70-SAFETY or Info@Optimum-USA.com